PCB Inspection Systems

Since its inception in 2000, ViTrox designs and manufactures innovative, leading-edge and cost-effective automated vision inspection equipment and system-on-chip embedded electronics devices for the semiconductor and electronics packaging industries. ViTrox's core products are its Machine Vision System (MVS), Automated Board Inspection (ABI) and Integrated Industrial Embedded Solutions (IIES).

ViTrox serves customers from semiconductor Outsourced Assembly and Test (OSAT) companies, printed circuit board manufacturers, electronics assemblies companies, Original Equipment Manufacturers (OEM), Original Design Manufacturers (ODM), Electronics Manufacturing Services (EMS) providers and Contract Manufacturers (CM) around the world.

ViTrox serves customers from semiconductor Outsourced Assembly and Test (OSAT) companies, printed circuit board manufacturers, electronics assemblies companies, Original Equipment Manufacturers (OEM), Original Design Manufacturers (ODM), Electronics Manufacturing Services (EMS) providers and Contract Manufacturers (CM) around the world.

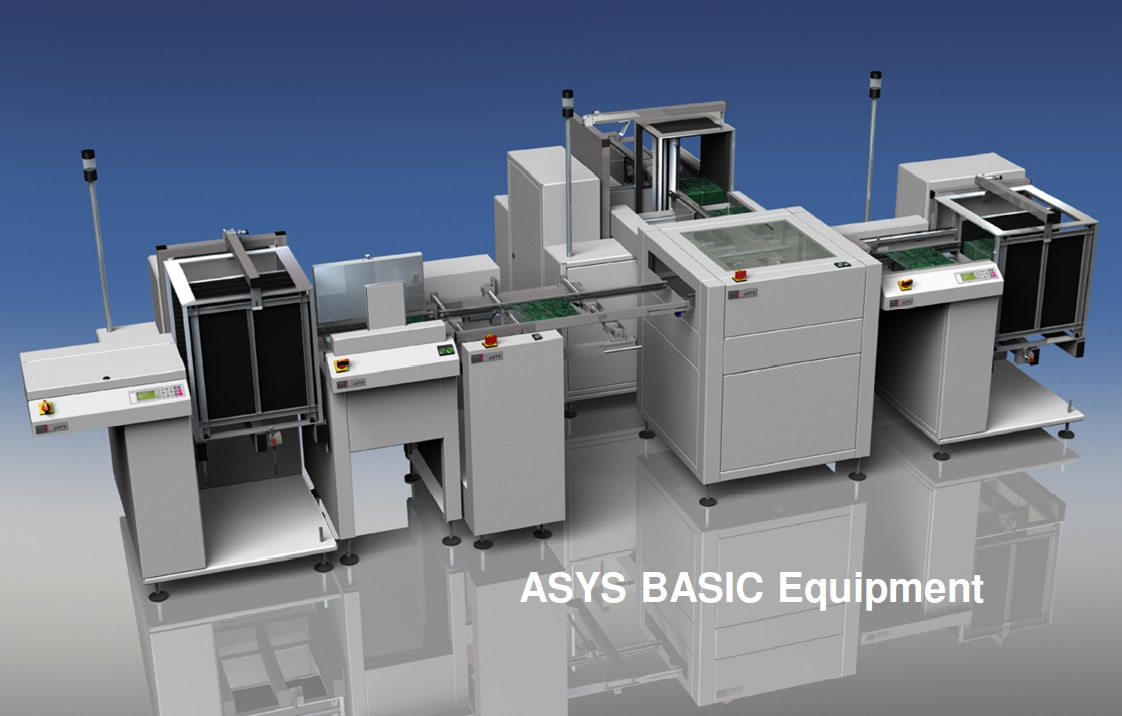

Handling, Marking & Verification, Printing, Depaneling, Storage, Final Asssembly

The roots of the ASYS Group are in automation. The initial idea of offering standard systems for handling in electronics production marked the beginning of a steep success curve. In the meantime, the ASYS Group covers 75 percent of an electronics production with its products. The initial urge to automate is becoming established in all product developments. Top of the line systems in Stencil Printers, Depaneling, Laser Marking, Handling, and Storage allow Asys to lead the future in factory automation.

PrintingWith the EKRA brand we offer scalable printing systems for your electronics production. With our stencil and screen printers, you can apply solder paste to printed circuit boards precisely and with repeatable accuracy. At EKRA, we pay full attention to the details so that you get a custom solution for your production that meets your needs now and in the future. With our broad product portfolio, we can offer solutions for every application. From 24/7 to small series production - we accompany you individually with the printer that suits you best.

|

DepanelingRegardless of material, size or contour - our DIVISIO depaneling systems depanels your printed circuit board from the panel with a precision of 10µm. Whether as an stand alone solution, inline or offline system - we supply a machine that is perfectly oriented to your requirements and your production. In doing so, we rely on proven separation processes: sawing, routing or laser cutting. The 1000th system sold speaks for the success and experience in 20 years of DIVISIO depaneling system

|

Laser MarkingWe offer a comprehensive product portfolio of traceability systems to meet the ever-increasing demands of traceability. High-precision marking in the smallest possible space in order to meet the highest cycle time requirements, up to reading multipanels in the shortest possible time, are part of the range of tasks of our systems. Furthermore, our SIMPLEX User Interface offers unique possibilities to minimize setup times. Offline programming are advantages for reacting quickly and effectively to new production requirements.

|

High-End Handling with added value |

Storage: Magazines, Boxes, Components |

Industry Leader in Spray Coating, Dispense Systems and Curing ovens

SCS leads the industry with state-of-the-art coating, curing and testing systems. From laboratory applications to advanced production systems, SCS customers benefit from technology that delivers unmatched accuracy and reliability.

Conformal Coat and Dispensing systems

Water and Chemistry inline washers for Printed Circuit Boards

AAT is at the forefront of engineering and manufacturing high performance cleaning systems for over 35 years, delivering solutions worldwide. Austin American Technology was founded in 1986 by Lead Chemist, Steve Stach.

MADE IN USA Selective Soldering Systems

Designed to elevate your manufacturing processes. Engineered with precision and efficiency in mind, the PHOENIX-IL offers unparalleled accuracy in applying solder to specific components on PCB’s, significantly reducing the risk of defects and improving overall quality. The PHOENIX-IL is equipped with the new EmberX software controls, enabling seamless integration into existing production lines and offering user-friendly interface for effortless operation. With its superior performance and reliability, the PHOENIX-IL is designed to ensure your products meet the highest standards of excellence.

Standard Features: Windows operating system with the EmberX Software

Dual Monitors For simultaneous video feed

Fiducial recognition for automatic position and rotation

correction

HD1080p Cameras for high resolution process viewing

and PCB programming Offline Programming

Automated wave height check/adjust

Atomizing flux applicator

Lead alloy solder pot and pump assembly (lead free available)

Automated solder level verification and fill

SMEMA edge conveyor with pneumatic board clamping

and program controlled width adjust

Warranty one year covering the entire machine

Dual Monitors For simultaneous video feed

Fiducial recognition for automatic position and rotation

correction

HD1080p Cameras for high resolution process viewing

and PCB programming Offline Programming

Automated wave height check/adjust

Atomizing flux applicator

Lead alloy solder pot and pump assembly (lead free available)

Automated solder level verification and fill

SMEMA edge conveyor with pneumatic board clamping

and program controlled width adjust

Warranty one year covering the entire machine

|

| ||||

BGA Rework Systems, X-Ray Systems, X-Ray Counters

Advanced electronics manufacturing equipment supplier providing intelligent imaging applications, X-ray inspection, PCB rework solutions and services for a variety of electronics and industrial markets worldwide.

SUMMIT Rework Systems

With the largest installed base of rework systems in the world, VJ Electronix is confident that we can meet any rework need that you have. Our systems are designed to rework components ranging from 01005 all the way to 120mm and we have a large range of applications including connectors, package-on-package, RF shields, and more! High-level automation, intuitive software, and easy set up help minimize operator intervention and simplify your most difficult rework processes.

Flying Probe / ICT Test Systems

SPEA automatic flying probe testers for electronic boards stand out for their unsurpassed throughput performance and for their excellent fault coverage.

The main advantage of flying probe testers is that they are immediately ready to test every new product, without needing any specific interface fixture or testability study.

To this feature, SPEA systems add complete automation both in test program development and in system operation. Starting from CAD files, the generation of an in-circuit test program is completely automatic, as well as the fine-tuning and stabilisation of the measurements: in a few hours, the test program is ready to run. The tester operation can be completely automatic, without any operator’s intervention: with the aid of SPEA Board Handling Equipment, the flying prober can run over an entire work shift or a weekend in full autonomy.

SPEA automatic flying probe testers for electronic boards stand out for their unsurpassed throughput performance and for their excellent fault coverage.

The main advantage of flying probe testers is that they are immediately ready to test every new product, without needing any specific interface fixture or testability study.

To this feature, SPEA systems add complete automation both in test program development and in system operation. Starting from CAD files, the generation of an in-circuit test program is completely automatic, as well as the fine-tuning and stabilisation of the measurements: in a few hours, the test program is ready to run. The tester operation can be completely automatic, without any operator’s intervention: with the aid of SPEA Board Handling Equipment, the flying prober can run over an entire work shift or a weekend in full autonomy.

SPEA automatic flying probe testers for electronic boards stand out for their unsurpassed throughput performance and for their excellent fault coverage.

|

SPEA automatic flying probe testers for electronic boards stand out for their unsurpassed throughput performance and for their excellent fault coverage.

The main advantage of flying probe testers is that they are immediately ready to test every new product, without needing any specific interface fixture or testability study. To this feature, SPEA systems add complete automation both in test program development and in system operation. Starting from CAD files, the generation of an in-circuit test program is completely automatic, as well as the fine-tuning and stabilisation of the measurements: in a few hours, the test program is ready to run. |

|

SPEA’s ICT Testers ensure zero-failure escape and can reliably and consistently test a wide range of electronic boards for automotive, energy, medical, aerospace, lighting, and internet of things (IoT) applications.

Automatic and manual board handling, high throughput, consistent and repeatable results, full scalability, on-field upgradeability – these exclusive features allow SPEA’s ICT Testers to meet the testing and throughput needs of electronics manufacturers, with reliable and flexible test equipment for long-lasting and intensive use over the years. |

Condensation Solder (Vapor-Phase Reflow)

The Condenso series can solder even the most difficult assemblies quickly and dependably, at temperatures up to 240°C. In order to improve control of the condensation phase, Rehm has developed a patented injection process that allows the soldering procedure to be individually regulated. An optional vacuum module ensures void-free soldered joints – directly after the soldering process or as a pre-vacuum. Our systems let you adjust all parameters, such as pressure or temperature, flexibly – for the best soldering results that exactly match the requirements of your manufacturing.

|

The CondensoXC is a space-saving, powerful system for laboratory applications, small series production and prototyping. Exact profiling by means of the injection principle and the option of soldering under an inert atmosphere provides optimum soldering results. Void-free soldering can also be carried out easily with the vacuum option, which increases the reliability of assemblies significantly. With a footprint of just 2.3m², this system is specially designed for small series and is also ideal for prototype production. As a batch system, it can be used flexibly, irrespective of the production environment.

|

|

The CondensoXS smart is impressive thanks to its new chamber design and flexibility throughout the entire line. The new chamber design with a vertically opening or closing chamber ensures optimum hermetic sealing and thus reliable and reproducible results. The CondensoXS smart can be configured flexibly. Both manual and automatic loading and unloading concepts are available.

|

Factory Direct Bar Solder & Wire Solder for Electronics Manufacturing

Nathan Trotter was founded on strong values, a commitment to innovation and the development of successful customer partnerships. These timeless principles continue to inform our everyday operations, even as our team expands, customer needs change and priorities evolve. Today, Nathan Trotter remains a family-owned and operated business and has grown to include a recycling division, Tin Technology and Refining, as well as the only manufacturer of tin wine capsules in North America, Keystone Capsules.

|

Nathan Trotter is a leading manufacturer of solder bar and wire for use in electronic assembly, PCB fabrication, automotive, heat exchange, and power storage applications. These high-reliability markets demand a solder that provides optimal yields, minimal oxidation, and superior performance and Nathan Trotter consistently delivers. Success has been demonstrated in every application including through-hole technology (THT) wave soldering, HASL, dip coating, and plating.

FACTORY DIRECT PRICING 63/37 NT100Ge 99C HR95 SAC307 SAC305 | ||||||